- 您现在的位置:买卖IC网 > Sheet目录983 > HI5662EVAL2 (Intersil)EVALUATION PLATFORM HI5662

�� �

�

�

�Application� Note� 9823�

�Evaluation� Board� Layout� and� Power�

�Supplies�

�The� HI5662� evaluation� board� is� a� four� layer� board� with� a�

�layout� optimized� for� the� best� performance� of� the� ADC.�

�Included� in� the� application� note� are� electrical� schematics� of�

�the� evaluation� board,� a� component� parts� list,� a� component�

�placement� layout� drawing� and� reproductions� of� the� various�

�board� layers� used� in� the� board� stack-up.� The� user� should�

�feel� free� to� copy� the� layout� in� their� application.� Refer� to� the�

�component� layout� and� the� evaluation� board� electrical�

�schematic� for� the� following� discussions.�

�The� HI5662� monolithic� A/D� converter� has� been� designed�

�with� separate� analog� and� digital� supply� and� ground� pins� to�

�keep� digital� noise� out� of� the� analog� signal� path.� The�

�evaluation� board� provides� separate� low� impedance� analog�

�and� digital� ground� planes� on� layer� 2.� Since� the� analog� and�

�digital� ground� planes� are� connected� together� at� a� single�

�point� where� the� power� supplies� enter� the� board,� DO� NOT� tie�

�them� together� back� at� the� power� supplies.�

�The� analog� and� digital� power� planes� are� also� kept� separate�

�on� the� evaluation� board� and� should� be� driven� by� clean� linear�

�regulated� supplies.� The� external� power� supplies� are� hooked�

�up� with� the� twisted� pair� wires� soldered� to� the� plated� through�

�holes� marked� +5VAIN,� +5VAIN1,� -5VAIN,� +5VDIN,�

�+5VD1IN,� +5VD2IN,� AGND� and� DGND.� The� +5VDIN,�

�+5VD1IN� and� +5VD2IN� are� digital� supplies� and� are� returned�

�to� DGND.� The� +5VAIN,� +5VAIN1� and� -5VAIN� are� the� analog�

�supplies� and� are� returned� to� AGND.� Table� 1� lists� the�

�operational� supply� voltages,� typical� current� consumption� and�

�the� evaluation� board� circuit� function� being� powered.� Single�

�supply� operation� of� the� converter� is� possible� but� the� overall�

�performance� of� the� converter� may� degrade.�

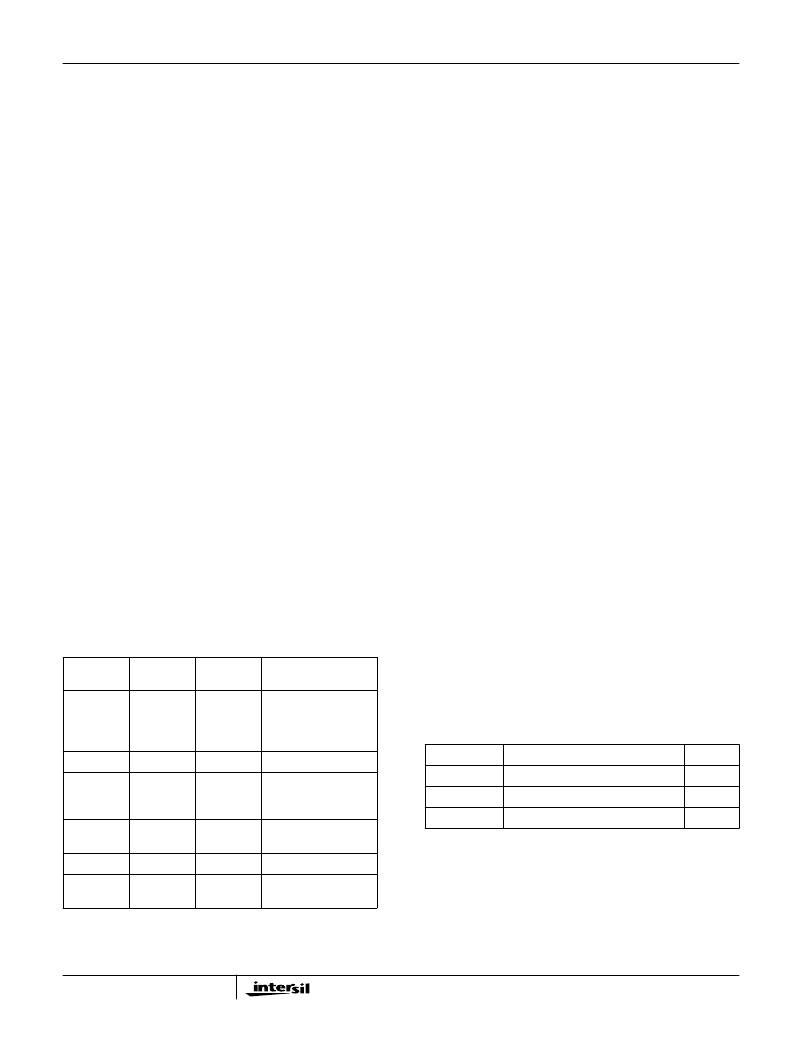

�TABLE� 1.� HI5662EVAL2� EVALUATION� BOARD� POWER�

�SUPPLIES�

�Sample� Clock� Driver,� Timing� and� I/O�

�In� order� to� ensure� rated� performance� of� the� HI5662,� the� duty�

�cycle� of� the� sample� clock� should� be� held� at� 50%� ±� 5%.� It� must�

�also� have� low� phase� noise� and� operate� at� standard� TTL� levels.�

�A� CMOS� inverter� (U7)� used� as� a� voltage� comparator� is�

�provided� on� the� evaluation� board� to� generate� the� sampling�

�clock� for� the� HI5662� when� a� sinewave� (<� 2V� P-P� )� or�

�squarewave� clock� is� applied� to� the� CLK� input� (J3)� of� the�

�evaluation� board.� A� potentiometer� (VR2)� is� provided� to� allow�

�the� user� to� adjust� the� duty� cycle� of� the� sampling� clock� to�

�obtain� the� best� performance� from� the� ADC� and� to� allow� the�

�user� to� investigate� the� effects� of� expected� duty� cycle�

�variations� on� the� performance� of� the� converter.� The� HI5662�

�clock� input� trigger� level� is� approximately� 1.5V.� Therefore,� the�

�duty� cycle� of� the� sampling� clock� should� be� measured� at� this�

�1.5V� trigger� level.� U7-2� provides� a� convenient� point� to�

�monitor� the� sample� clock� duty� cycle� and� make� any� required�

�adjustments.�

�Figure� 1� shows� the� sample� clock� and� digital� data� timing�

�relationship� for� the� evaluation� board.� The� data�

�corresponding� to� a� particular� sample� will� be� available� at� the�

�digital� data� outputs� of� the� HI5662� after� the� data� latency� time,�

�t� LAT� ,� of� 6� sample� clock� cycles� plus� the� HI5662� digital� data�

�output� delay,� t� OD� .� Table� 2� lists� the� values� that� can� be�

�expected� for� the� indicated� timing� delays.� Refer� to� the� HI5662�

�data� sheet� for� additional� timing� information.�

�The� sample� clock� and� digital� output� data� signals� are� made�

�available� through� two� connectors� contained� on� the�

�evaluation� board.� The� line� buffering� provided� by� the� data�

�output� latches� allows� for� driving� long� leads� or� analyzer�

�inputs.� These� data� latches� are� not� necessary� for� the� digital�

�output� data� if� the� load� presented� to� the� converter� does� not�

�exceed� the� data� sheet� load� limits� of� 100mA� and� 15pF.� The�

�P2� I/O� connector� allows� the� evaluation� board� to� be�

�interfaced� to� the� DSP� evaluation� boards� available� from�

�POWER�

�SUPPLY�

�+5VAIN�

�NOMINAL�

�VALUE�

�5.0V� ±� 5%�

�CURRENT�

�(TYP)�

�51mA�

�FUNCTION(S)�

�SUPPLIED�

�Analog� Input� Op� Amps,�

�Reference� Voltage� Op�

�Intersil.� Alternatively,� the� digital� output� data� and� sample�

�clock� can� also� be� accessed� by� clipping� the� test� leads� of� a�

�logic� analyzer� or� data� acquisition� system� onto� the� I/O� pins� of�

�connector� header� P1.�

�Amps,� Bandgap�

�Reference�

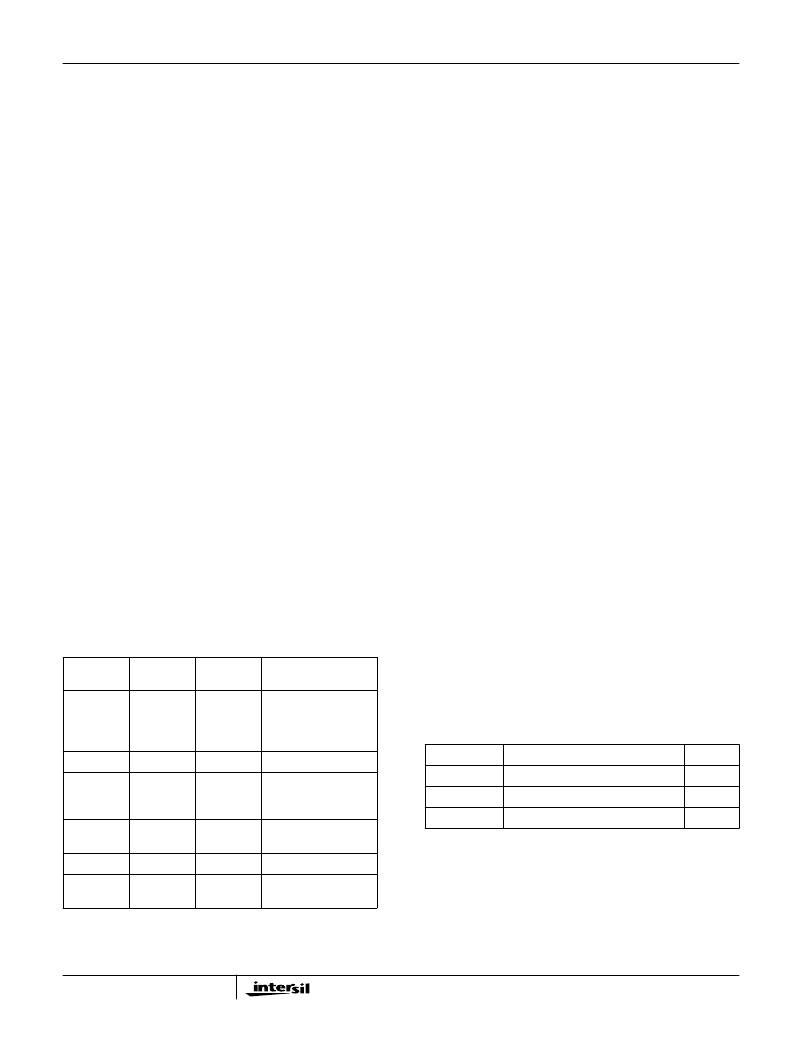

�TABLE� 2.� TIMING� SPECIFICATIONS�

�+5VA1IN�

�-5VAIN�

�+5VDIN�

�5.0V� ±� 5%�

�-5.0V� ±� 5%�

�5.0V� ±� 5%�

�73mA�

�50mA�

�15mA�

�A/D� AV� CC1� and� AV� CC2�

�Analog� Input� Op� Amps,�

�Reference� Voltage� Op�

�Amps�

�Sample� Clock�

�PARAMETER�

�t� OD�

�t� PD1�

�t� PD2�

�DESCRIPTION�

�HI5662� Digital� Output� Data� Delay�

�U7� Prop� Delay�

�U10/11� Prop� Delay�

�TYP�

�11ns�

�9ns�

�4.5ns�

�+5VD1IN�

�+5VD2IN�

�5.0V� ±� 5%�

�5.0V� ±� 5%� or�

�3.0V� ±� 10%�

�61mA�

�4.5mA�

�Generator� and� D-FF’s�

�A/D� DV� CC1� and� DV� CC2�

�A/D� DV� CC3�

�HI5662� Performance� Characterization�

�Dynamic� testing� is� used� to� evaluate� the� performance� of� the�

�HI5662� A/D� converter.� Among� the� tests� performed� are�

�Signal-to-Noise� and� Distortion� Ratio� (SINAD),� Signal-to-�

�Noise� Ratio� (SNR),� Total� Harmonic� Distortion� (THD),�

�Spurious� Free� Dynamic� Range� (SFDR)� and� Intermodulation�

�Distortion� (IMD).�

�3-2�

�发布紧急采购,3分钟左右您将得到回复。

相关PDF资料

HI5714EVAL

EVALUATION PLATFORM HI5714

HI5728EVAL1

EVALUATION PLATFORM TQFPHI5728

HI5731-EVS

EVALUATION PLATFORM SOIC HI5731

HI5741-EVS

EVALUATION PLATFORM HI5741

HI5760EVAL1

EVALUATION PLATFORM SOIC HI5760

HI5762EVAL2

EVALUATION MOD FOR HI5762 AMP

HI5767EVAL1

EVALUATION PLATFORM HI5767

HI5767EVAL2

EVALUATION PLATFORM HI5767

相关代理商/技术参数

HI5662IN

制造商:未知厂家 制造商全称:未知厂家 功能描述:Converter IC

HI5667

制造商:INTERSIL 制造商全称:Intersil Corporation 功能描述:8-Bit, 60MSPS A/D Converter with Internal Voltage Reference

HI5667/6CA

制造商:Rochester Electronics LLC 功能描述:A/D, 8-BIT,60MSPS,COM TEMP,28 SSOP,TTL/CMOS (HI5767/6, 10- - Bulk

HI5667/6CB

制造商:Rochester Electronics LLC 功能描述:- Bulk

HI5667EVAL2

制造商:Rochester Electronics LLC 功能描述:- Bulk

HI5675

制造商:INTERSIL 制造商全称:Intersil Corporation 功能描述:8-Bit, 20MSPS, Flash A/D Converter

HI5675_03

制造商:INTERSIL 制造商全称:Intersil Corporation 功能描述:8-Bit, 20MSPS, Flash A/D Converter

HI5675JCB

制造商:Rochester Electronics LLC 功能描述:- Bulk